DTF Technology

What is it?

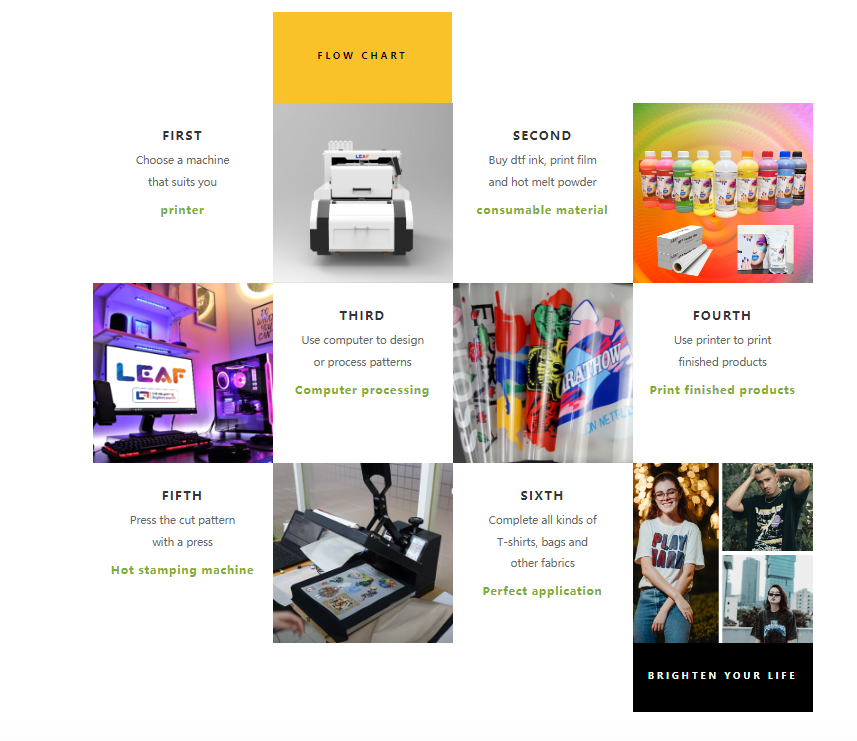

Direct-to-film printing, known as DTF, is a heat-transfer-based print technology.

The process begins with water-based pigment ink printing designs onto a transfer film(PET),which is then covered with a thermo-adhesive powder(TPU) and transferred with a heat press to the final substrate.

The application of DTF printing is huge, one of the most common items created by DTF printing is T-shirts, always in high demand,T-shirts can be made for various purposes from schools to sports to other organizations. Besides T-shirts, DTF printing can alsocreate pockets on hoodies or shirts, hats, printed tags, shoes, jeans/pants, bags, flags, banners, koozies, and other fabric items.However, the DTF solution is more complex than the process described.

The printing process at least includes three pieces of equipment: an ink-jet printer, a powder spray and shaking machine, and a heat press. Also, the consumables use the digital ink, transfer film, and the TPU powder. Those factors constitute a systematic engineering, every factor needs a professional selection and makes the best matching total solution with the best quality and reasonable costs.

Why DTF Technology

Labor Saving

Easy To Operate

Single printing

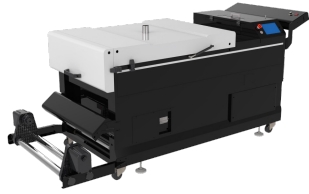

DTF Printer E Series

LF-370i

Printing Width: 37cm/14inch

Print heads: 2pcs*Epson i1600-A1

Printer + Shaker + Purifier

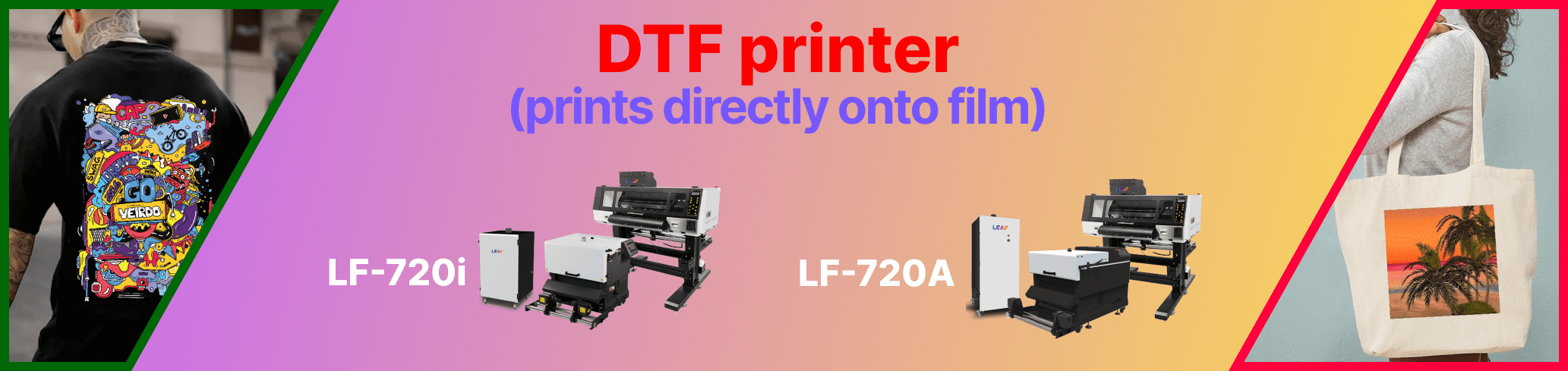

LF-720i

Printing Width: 60cm/24inch

Print heads: 2pcs*Epson i3200-A1

Printer + Shaker + Purifier

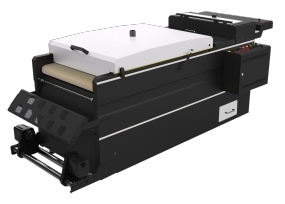

DTF Printer M Series

LF-720A

Printing Width: 60cm/24inch

Print heads: 2pcs*Epson i3200-A1

Printer + Shaker + Purifier

LF-740A

Printing Width: 60cm/24inch

Print heads: 4pcs*Epson i3200-A1

Printer + Shaker + Purifier

H Series

LF-570i

(Printer & Shaker 2-in-1)

Printing Width: 60cm/24inch

Print heads: 2pcs*Epson i3200-A1

LF-740SF

8 Colors with Fluorescent color)

Printing Width: 60cm/24inch

Print heads: 3pcs*Epson i3200-A1

Environmental protection, no waste disposal

No stroke, no hollowing, no need to open the board, one piece starts printing

Small floor space, one person working

The pattern is ultra-thin, soft and elastic

Don’t worry about color deviation and firmness

Suitable for any fabric, low cost

What can a DTF printer do?

T-Shirts

Sweatshirts

Bags

Throw Pillows

Rucksacks

Mouse Pads

Canvas Shoes

Caps

What are you going to do?